Introduction to Condensate Pumps

What is a Condensate Pump?

Condensate pumps are vital components in the HVAC ecosystem, quietly ensuring that the water generated during the heating or cooling process is effectively managed and removed. These devices are designed to collect and transport condensation from air conditioning units, furnaces, and boilers away from the equipment to prevent water damage and maintain optimal operation.

Their role is often underestimated, but without them, the efficiency and safety of an HVAC system could be compromised.

The Science Behind It

The principle behind a condensate pump is relatively simple but ingenious. It leverages the basic physics of water movement to transport condensation from the HVAC system to an appropriate drainage point. This is typically achieved through a combination of a collection tank, a float switch, and a pump mechanism.

As condensation drips into the tank, the water level rises, activating the float switch once a certain level is reached. This, in turn, powers the pump to move the water through a discharge line, effectively keeping the HVAC system dry and functional.

Image by ASphotofamily on Freepik

Why Do We Need Condensate Pumps?

The necessity for condensate pumps stems from the inherent production of condensation in HVAC systems. High-efficiency systems, in particular, produce significant amounts of condensation as they operate. Without a means to remove this water, it can accumulate, leading to mold growth, structural damage, and a decline in air quality.

Condensate pumps address this issue head-on, ensuring that water is efficiently expelled from the system, thereby protecting the structure and health of the building's occupants.

Applications in HVAC Systems

Condensate pumps find their applications in a wide range of environments, from residential homes to commercial buildings and industrial facilities. Their versatility is a testament to their importance across different settings. In residential settings, they ensure that homes remain safe and comfortable.

In commercial and industrial environments, they are crucial for maintaining the operational integrity of large-scale HVAC systems, which are essential for both comfort and in some cases, operational processes.

How Condensate Pumps Work

The Mechanism

The mechanism of a condensate pump is a marvel of simplicity and efficiency. It consists of a reservoir to collect water, a float switch to sense the water level, and a pump to expel the collected water. The float switch plays a pivotal role in this system, acting as the trigger for the pump's operation.

As water levels in the reservoir reach a predetermined point, the float switch activates the pump, which then pushes the water out through a discharge line to a drain or external area.

The Role of the Float Switch

The float switch is arguably the heart of the condensate pump, governing its operation with precision. This component is responsible for detecting the water level within the pump's reservoir, ensuring that the pump activates at the right moment to remove the condensation efficiently.

It's a critical piece of the puzzle, providing both operational efficiency and a measure of safety by preventing overflow and potential water damage.

Safety Features

Modern condensate pumps are equipped with a variety of safety features designed to protect both the HVAC system and the premises. These may include overflow prevention mechanisms, such as secondary float switches that trigger an alarm or shut down the system if water levels rise too high.

Some models also feature alarms to alert homeowners or maintenance personnel of potential issues, allowing for prompt intervention before any damage occurs.

Preventing Water Damage

The role of condensate pumps in preventing water damage is invaluable. By efficiently managing and removing the water produced by HVAC systems, these pumps play a critical role in preserving the structural integrity of buildings.

They prevent the accumulation of water that could lead to mold growth, wood rot, and other forms of water damage, thereby saving homeowners and businesses significant repair costs over time.

Selecting the Right Condensate Pump

Considerations

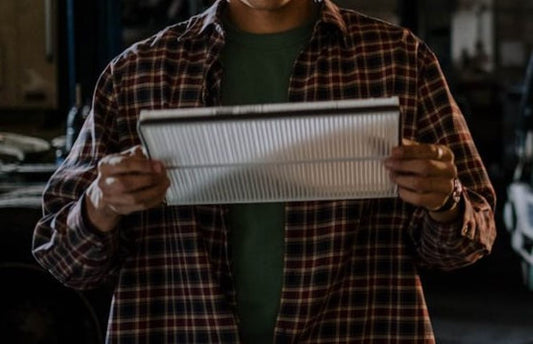

Choosing the right condensate pump involves several key considerations. The size of the HVAC system, the layout of the installation site, and the specific requirements of the system (such as the volume of condensation produced and the height the water needs to be pumped) are all critical factors.

Additionally, features such as pump capacity, noise level, and the presence of safety mechanisms should be taken into account to ensure optimal performance and protection.

Sizing and Capacity

The effectiveness of a condensate pump is heavily dependent on its size and capacity being matched to the needs of the HVAC system. A pump that's too small may not be able to handle the volume of water produced, leading to potential overflow issues.

Conversely, an overly large pump may be inefficient in terms of energy use. Understanding the specifications of your HVAC system and the conditions in which it operates is crucial for selecting a pump that can handle the job efficiently.

Installation Tips

Installing a condensate pump might initially appear complex, but with clear instructions and the right tools, it can be a manageable DIY project. Here’s how to ensure your condensate pump is installed correctly for optimal efficiency:

Choose the Right Location: The pump should be near the HVAC unit to efficiently collect condensate. Ensure it's also near a power source and a proper drainage area.

Connect to the HVAC Unit: Attach the condensate line from your HVAC unit to the pump. Make sure the connection is secure to prevent leaks.

Set Up the Discharge Line: Route the discharge line from the pump to a drain or outside your home. Ensure it has a downward slope to aid gravity in moving the water.

Test the Pump: Fill the pump reservoir with water until the float activates the pump. Check all connections for leaks and ensure water is being expelled through the discharge line.

Maintenance and Troubleshooting

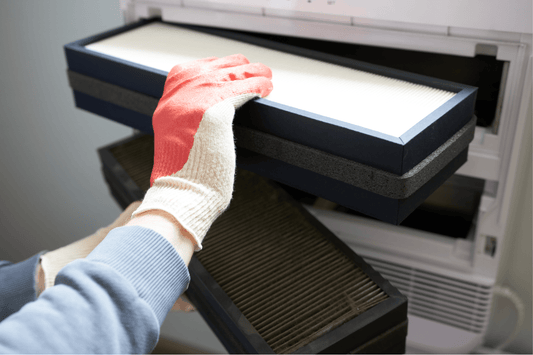

To ensure your condensate pump continues to run smoothly, regular maintenance is crucial. Here are some tips:

Clean the Reservoir: Remove any debris or algae buildup in the pump's reservoir to prevent clogs.

Inspect the Float Switch: Ensure the float switch moves freely and isn’t hindered by debris.

Check the Discharge Line: Regularly inspect the line for clogs or damage. A blocked line can cause the pump to overwork or fail.

Common troubleshooting includes checking for power issues, ensuring the pump is not overwhelmed by excessive water flow, and replacing the float switch if the pump fails to activate.

The Environmental Impact

Reducing Water Waste

Condensate pumps play a significant role in environmental conservation by efficiently managing water waste. By redirecting condensate away from sewer systems and towards appropriate disposal or reuse methods, these pumps help conserve water and reduce the burden on municipal water treatment facilities.

Energy Efficiency

Modern condensate pumps are designed with energy efficiency in mind. By using less electricity and operating only when necessary, these pumps contribute to lower household energy consumption, resulting in reduced energy bills and a smaller carbon footprint.

DIY vs. Professional Installation

When to DIY

DIY installation is suitable for those with basic plumbing and electrical knowledge. It's a cost-effective option for handy homeowners comfortable with following installation guides and safety precautions.

When to Call a Pro

Professional installation is recommended if the setup involves complex wiring, if local codes require professional installation, or if you're not comfortable undertaking the task yourself. A professional can ensure the installation meets all safety and performance standards.

Future of Condensate Pumps

Innovations in Design

The condensate pump market is witnessing continuous innovation, with newer models featuring advanced technologies such as automatic cleaning functions, noise reduction, and increased energy efficiency. These innovations aim to enhance the user experience and pump performance.

Smart Home Integration

With the rise of smart home technology, condensate pumps are becoming more intelligent. Future models are expected to offer remote monitoring and control capabilities, allowing homeowners to manage their HVAC systems more effectively and prevent issues before they arise, integrating seamlessly with other smart home devices for a fully connected home environment.

Conclusion

Condensate pumps may operate behind the scenes, but their contribution to the efficiency and safety of HVAC systems is undeniable. By understanding how these pumps work, their importance, and how to select and maintain them, homeowners and facility managers can ensure that their HVAC systems continue to operate smoothly and safely.

As technology advances, the integration of smart features and improvements in energy efficiency promise to make condensate pumps even more integral to HVAC system design and operation.

FAQs

What is the lifespan of a condensate pump?

The lifespan of a condensate pump can vary based on several factors, including the quality of the pump, the frequency of its use, and how well it is maintained. On average, a well-maintained condensate pump can last between 5 to 10 years. However, this is not a hard and fast rule. Some pumps may last longer with meticulous care and maintenance, while others might need replacement sooner due to heavy use or less optimal operating conditions.

Regular inspections and maintenance can help extend the life of your pump by identifying and addressing any issues before they lead to significant damage or failure.

Can I install a condensate pump myself?

Yes, installing a condensate pump is a task that many homeowners can undertake themselves, especially if they are handy and familiar with their HVAC system's basic components. Most condensate pump models come with installation instructions that are straightforward and easy to follow.

Additionally, there are numerous online tutorials and videos available that can guide you through the process. However, it's important to ensure you're comfortable with the installation process and understand the safety precautions. If you have any doubts or if the installation involves complex wiring or plumbing, it might be best to hire a professional.

How often should I perform maintenance on my condensate pump?

Regular maintenance is crucial for keeping your condensate pump in optimal working condition. It's recommended to perform a basic maintenance check at least once a year. This includes cleaning the pump's reservoir, checking the float switch for proper operation, and ensuring the discharge line is clear and free of obstructions.

Additionally, inspect the pump for any signs of wear or damage, such as cracks in the reservoir or issues with the power cord. Performing these maintenance tasks can help prevent malfunctions and extend the life of your pump.

What are the signs that my condensate pump needs to be replaced?

Several signs may indicate your condensate pump needs to be replaced, including:

- Frequent Overflows: If the pump's reservoir frequently overflows, it may indicate a failure in the pump mechanism or a blockage that cannot be cleared.

- Loud Noises: Unusual noises coming from the pump, such as grinding or gurgling sounds, can indicate mechanical issues.

- Continuous Operation: If the pump runs continuously without shutting off, it may suggest a problem with the float switch or a significant leak in the system.

- Visible Damage: Cracks in the pump's reservoir or damage to the electrical components are clear signs that the pump needs to be replaced.

If you encounter any of these issues, it's advisable to consult with a professional to determine whether repair or replacement is the best course of action.

Can a condensate pump improve the efficiency of my HVAC system?

While a condensate pump itself does not directly improve the efficiency of an HVAC system, it plays a critical role in ensuring the system operates smoothly and efficiently. By effectively removing condensate, the pump prevents water damage and mold growth, which can affect the air quality and efficiency of your HVAC system.

A well-functioning condensate pump also helps maintain the optimal performance of your HVAC system by ensuring that excess moisture is not causing corrosion or other damage to the system's components. In this way, a condensate pump contributes to the overall efficiency and longevity of your HVAC system.

Featured image: Image by fanjianhua on Freepik