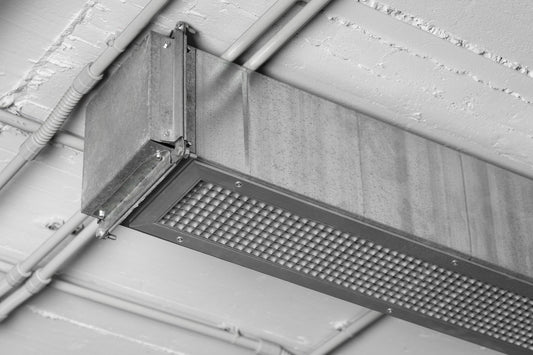

Introduction to HVAC System Components

Ever wandered into a room cooled to perfection on a blistering hot day and pondered over the engineering marvel behind that immediate comfort? It's not alchemy but the pinnacle of science and engineering working harmoniously. Nestled within the intricate maze of HVAC (Heating, Ventilation, and Air Conditioning) systems is an often-overlooked champion known as the liquid line filter drier.

Though it may not bask in the spotlight, its role is pivotal for the seamless functionality and durability of the HVAC system.

The Refrigerant: HVAC's Vital Fluid

Think of refrigerants as the circulatory system of any HVAC unit, tasked with the crucial job of transporting heat to and fro, enabling our environments to stay chilled or warmed up just right. However, for this cycle to operate flawlessly, the refrigerant must be pristine, devoid of any contaminants or moisture. Enter the unsung hero of our HVAC tale, the liquid line filter drier, standing guard to ensure nothing less than perfection in our refrigerant's journey.

Tracing the Refrigerant's Path: Compression to Liquid State

To truly grasp the significance of the liquid line filter drier, let's embark on a brief exploration of the refrigerant's voyage. Post-compression, the refrigerant transforms into a high-pressure, heated gas, meandering through the condenser. It's here that it bids adieu to its heat, embracing a liquid form. This newly liquified refrigerant, cool yet still under considerable pressure, embarks on its next leg through the liquid line, making its way to the evaporator.

Image by maniacvector on Freepik

Shining a Light on Liquid Line Filter Driers

What Exactly is a Liquid Line Filter Drier?

Picture the HVAC ecosystem: the system as the body, the refrigerant as its life-sustaining fluid, and the liquid line filter drier as a vital organ, akin to the kidney. Much like how the kidney purifies blood, the liquid line filter drier ensures the refrigerant is devoid of any impurities. Positioned strategically in the liquid line, this compact yet mighty component acts as a sentinel, guaranteeing only the cleanest, moisture-free refrigerant reaches the evaporator.

The Dual Mission of Filter Driers

Capturing Particulate Matter

Firstly, the filter drier plays the critical role of intercepting any particulate matter floating within the refrigerant. These could be minuscule fragments of metal due to internal wear and tear, or even dust particles that sneak in during maintenance or installation phases.

Moisture Absorption: A Key to Integrity

Secondly, and perhaps more crucially, it's tasked with moisture absorption. Moisture, when mixed with the system's lubricants, can turn into corrosive acids, pave the way for ice blockages, and diminish the system's efficiency. Thanks to the desiccant material housed within, the filter drier adeptly traps this moisture, preserving the refrigerant's purity and, by extension, the system's overall health.

Installation and Maintenance

Best Practices for Filter Drier Installation

Proper installation of a liquid line filter drier is not just a good practice; it's a necessity. The placement of this component can significantly impact the efficiency and longevity of your HVAC system. Ideally, it should be installed in a location that's both protective of the system and convenient for maintenance activities. The orientation should also be considered, ensuring that the flow of refrigerant matches the arrow on the filter drier, which indicates the direction of flow. This careful attention to detail during installation can prevent issues related to improper refrigerant flow, which could lead to system inefficiency or failure.

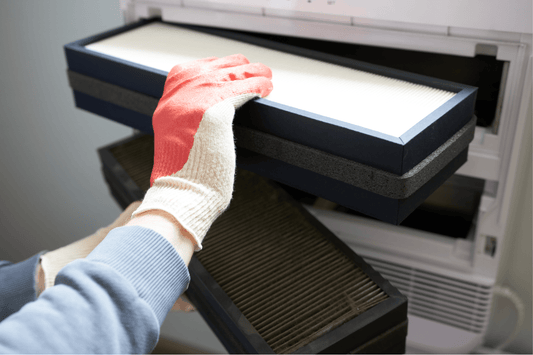

The Importance of Regular Maintenance

Think of your HVAC system like a car. Just as a vehicle needs regular oil changes and inspections, your HVAC system requires consistent maintenance to operate at its best. The filter drier, much like an oil filter, plays a crucial role in this maintenance routine. Technicians should inspect the filter drier during regular HVAC check-ups, looking for signs of saturation or blockage. Ignoring these signs can lead to increased operating costs, reduced system efficiency, and, ultimately, system failure.

Image by fabrikasimf on Freepik

The Impact of Filter Driers on System Efficiency and Longevity

Enhancing System Efficiency

A well-maintained filter drier is instrumental in ensuring that your HVAC system runs smoothly. By removing contaminants and moisture from the refrigerant, the filter drier helps maintain the refrigerant's thermodynamic properties, allowing for optimal heat exchange. This, in turn, ensures that your system doesn't have to work overtime to cool or heat your space, thereby enhancing overall system efficiency and reducing energy consumption.

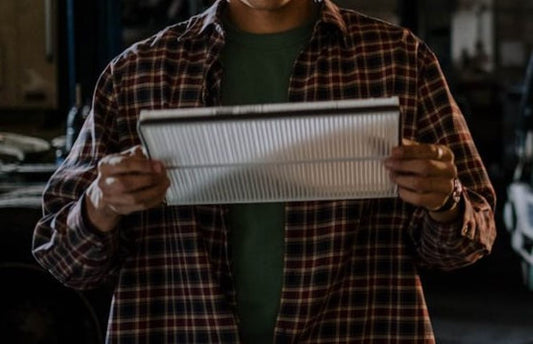

Extending the Life of HVAC Systems

The benefits of a liquid line filter drier extend beyond just operational efficiency; they also contribute significantly to the longevity of your HVAC system. By preventing the accumulation of harmful contaminants and moisture, filter driers protect critical components like compressors and evaporators from corrosion and wear. This proactive protection can save you from costly repairs and replacements down the line, making the filter drier a key player in the longevity of your HVAC system.

Photo by Allan Mas

Conclusion

The liquid line filter drier, though small and often overlooked, is a powerhouse of protection and efficiency for your HVAC system. By understanding its role, ensuring proper installation, and maintaining it regularly, you can enhance your system's performance, extend its lifespan, and save on energy costs. Remember, a little attention to this crucial component can lead to significant benefits for your comfort and your wallet.

FAQs

What happens if the liquid line filter drier is not replaced regularly?

Not replacing the filter drier can lead to a buildup of moisture and contaminants in the refrigerant, which can cause system inefficiencies, increased energy consumption, and potential damage to components like the compressor and evaporator coils.

Can a clogged filter drier cause my HVAC system to fail?

Yes, a clogged filter drier can restrict the flow of refrigerant, leading to reduced cooling or heating efficiency. In severe cases, it can cause the system to overheat and fail.

How often should the filter drier be replaced?

There's no one-size-fits-all answer to this question, as it depends on the system's usage and the environment it operates in. However, it's generally recommended to replace the filter drier whenever the system is opened for maintenance or repair.

What are the signs of a failing liquid line filter drier?

Signs include a temperature drop across the filter drier, visible signs of corrosion, or a decrease in system efficiency. If you suspect your filter drier is failing, it's best to consult a professional technician.

Can I replace the liquid line filter drier myself, or should I call a professional?

While it's possible for individuals with HVAC experience to replace a filter drier, it's generally recommended to have a professional do it. This ensures that the system is properly evacuated and recharged, and that the filter drier is installed correctly.

Featured image: Photo by Andrea Piacquadio