Introduction to Digital HVAC Gauges

In the fast-paced world of HVAC maintenance and repair, the introduction of digital HVAC gauges has been nothing short of revolutionary. These sophisticated tools have transformed traditional practices, making diagnostics quicker, more accurate, and far less prone to human error. Unlike their analog predecessors, which required manual interpretation of needle positions on a dial, digital gauges present precise measurements on clear, easy-to-read displays. This advancement not only speeds up the diagnostic process but also enhances the accuracy of the readings, ensuring that HVAC systems are assessed and serviced with unparalleled precision.

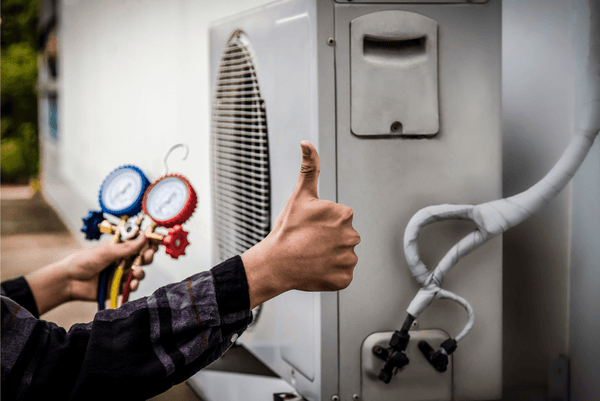

Image by DC Studio on Freepik

The Evolution from Analog to Digital

The shift from analog to digital in the HVAC industry mirrors broader technological advancements across various sectors. Analog gauges, while reliable, often necessitated a level of interpretation and conversion that could introduce errors. Digital gauges streamline these processes by automatically converting pressure readings into temperatures, displaying both in real-time. This evolution signifies a move towards greater efficiency and reliability in HVAC system maintenance, allowing technicians to focus more on analysis and less on the mechanics of measurement.

Key Features of Digital HVAC Gauges

Digital HVAC gauges come packed with features that set them apart from their analog counterparts. One of the most significant is the ability to store and select from multiple refrigerant profiles. This feature is crucial given the wide variety of refrigerants used in different systems. Additionally, many digital gauges offer Bluetooth connectivity, enabling technicians to monitor system performance remotely and record data directly to a smartphone or tablet for further analysis. This connectivity not only facilitates a more thorough diagnostic process but also allows for the creation of detailed service reports that can be shared instantly with clients or team members.

Why Digital Gauges Are a Game-Changer

Precision and Accuracy

The hallmark of digital HVAC gauges is their precision. The ability to provide exact readings down to the smallest unit eliminates the guesswork associated with analog gauges. This precision is particularly vital when working with systems that operate within very tight pressure and temperature ranges. Accurate diagnostics ensure that systems are not undercharged or overcharged with refrigerant, both of which can lead to inefficient operation and potential damage over time.

Ease of Use and Efficiency

Digital gauges are designed with the user in mind. Their digital displays are not only easier to read but also provide all the necessary information at a glance. This user-friendly design, combined with the speed at which digital gauges can offer readings, allows technicians to complete diagnostics more quickly, increasing the number of service calls they can handle. Moreover, the intuitive nature of these tools means that even technicians new to the field can quickly learn to use them effectively, reducing training time and costs.

Advanced Functionalities

Beyond basic pressure and temperature measurements, digital HVAC gauges offer a range of advanced functionalities. Leak testing, vacuum measurement, and the calculation of superheat and subcooling are just a few examples. These features enable technicians to conduct a comprehensive assessment of an HVAC system's performance, identifying potential issues before they become major problems. The ability to perform such detailed diagnostics not only enhances the service provided to clients but also contributes to the longevity and efficiency of HVAC systems.

Choosing the Right Digital HVAC Gauge

Considerations for New Technicians

For those new to the HVAC field, the array of digital gauge options can be overwhelming. It's important for new technicians to start with a gauge that offers the basic functionalities needed to perform most HVAC tasks. This approach allows them to become comfortable with digital diagnostics without being overwhelmed by too many features. As they gain experience and familiarity with different types of HVAC systems, they can then consider upgrading to more advanced gauges that offer additional functionalities and customization options.

Recommendations for Seasoned Technicians

Experienced technicians, on the other hand, will find value in the most advanced digital HVAC gauges available. These gauges offer features like wireless connectivity, extensive refrigerant profiles, and integrated vacuum measurements, all of which can significantly streamline and enhance the diagnostic process. For seasoned technicians, these advanced features are not just conveniences; they are essential tools that enable them to provide the highest level of service.

How to Maximize the Use of Digital HVAC Gauges

Best Practices for Maintenance and Diagnostics

To fully benefit from the capabilities of digital HVAC gauges, technicians should adhere to a set of best practices. Regular calibration is crucial to ensure the accuracy of readings. Proper handling and storage of the gauges can prevent damage and extend their lifespan. Additionally, technicians should make full use of the gauges' features, such as data logging and remote monitoring, to conduct thorough diagnostics and maintenance. Understanding how to interpret the data provided by the gauges is also key, as this knowledge allows technicians to make informed decisions about system adjustments and repairs.

Understanding the Data

The data provided by digital HVAC gauges is a goldmine of information about the health and performance of HVAC systems. Technicians must understand how to interpret this data correctly. For example, pressure readings can indicate whether a system is properly charged with refrigerant, while temperature measurements can reveal potential issues with airflow or system components. By mastering the interpretation of this data, technicians can diagnose issues more accurately and recommend the most effective solutions.

Image by pvproductions on Freepik

Conclusion

Digital HVAC gauges represent a significant advancement in the tools available to HVAC technicians. They offer a combination of precision, efficiency, and advanced functionalities that can significantly enhance the maintenance and repair of HVAC systems. Whether you are a new technician just starting out or a seasoned professional looking to improve your workflow, there is a digital HVAC gauge that can meet your needs. Embracing these tools is essential for anyone looking to provide the highest level of service in the HVAC industry.

FAQs

Can digital HVAC gauges be used with all types of refrigerants?

Yes, most digital HVAC gauges are designed to be compatible with a wide range of refrigerants, making them versatile tools for technicians who work with various HVAC systems.

How often do digital HVAC gauges need to be calibrated?

While the specific frequency can vary depending on the manufacturer's recommendations, it is generally advised to calibrate digital HVAC gauges annually to ensure ongoing accuracy.

Are digital HVAC gauges difficult to learn how to use?

Digital HVAC gauges are designed with user-friendly interfaces that make them accessible to technicians of all experience levels. Many models come with instructional materials or tutorials to help users get started.

Can digital HVAC gauges withstand rough handling in the field?

Yes, many digital HVAC gauges are built to endure the rigors of fieldwork, featuring durable designs and protective cases to withstand bumps, drops, and exposure to various environmental conditions.

Do digital HVAC gauges eliminate the need for other diagnostic tools?

While digital HVAC gauges provide comprehensive data that can aid in diagnostics, they are part of a broader toolkit that technicians use to maintain and repair HVAC systems. Other tools and equipment may still be necessary for specific tasks or in-depth system analysis.

Image by pvproductions on Freepik