Introduction to Filter Driers

In the complex ecosystem of HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) systems, each component plays a pivotal role in ensuring operational efficiency and longevity. Among these, filter driers are crucial yet often underrated heroes, safeguarding the system's health by maintaining the purity and dryness of the refrigerant. This guide offers an in-depth exploration of filter driers, highlighting their importance, functionality, and maintenance to underscore their indispensable role in HVACR systems.

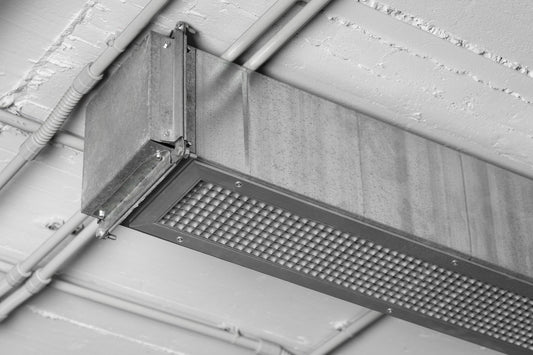

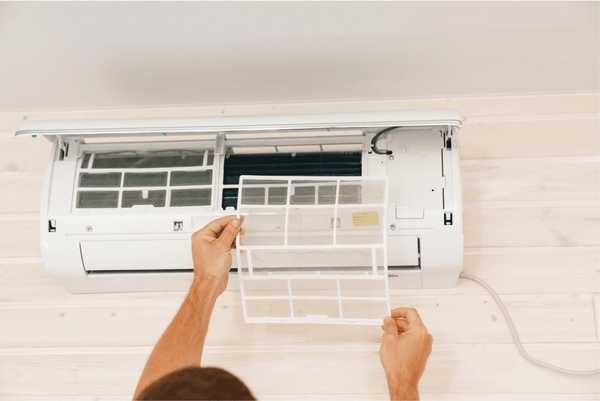

Image by DC Studio on Freepik

What Are Filter Driers?

Imagine an HVACR system as a living organism, with the refrigerant serving as its lifeblood. Just as clean blood is vital for the health of the organism, clean and dry refrigerant is essential for the efficient operation of an HVACR system. Filter driers act as the kidneys of this system, filtering out contaminants and moisture from the refrigerant. Positioned strategically within the refrigeration cycle, they perform dual functions: trapping particulate matter and absorbing moisture, ensuring that only the purest refrigerant circulates through the system. This not only safeguards the system's components but also optimizes its performance, making filter driers a linchpin in the HVACR system's efficiency and longevity.

Why Are Filter Driers Important?

The significance of filter driers in HVACR systems cannot be overstated. Moisture within the system can lead to the formation of acids when it reacts with refrigerants and lubricants. These acids can corrode metal components, leading to leaks, component failures, and a significant reduction in system efficiency. Particulate matter, on the other hand, can clog narrow passages and damage sensitive components, leading to wear and tear. By removing these contaminants, filter driers protect the system, ensuring it operates at peak efficiency and prolonging its lifespan.

The Mechanics of Filter Driers

Understanding the operation of filter driers is essential to appreciate their value fully. Their process can be broken down into two main functions: filtering impurities and drying the refrigerant.

Filtering Out Impurities

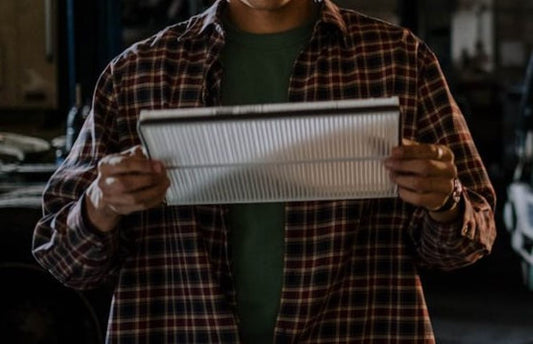

The filtering capability of a filter drier is achieved through a dense mesh or sieve, designed to capture particulate matter as the refrigerant flows through. This mesh is fine enough to trap even the smallest debris, preventing it from circulating through the system and potentially causing blockages or damaging sensitive components like compressors and expansion valves. This section could delve into the types of materials used for the mesh, the engineering behind its design, and real-world implications of its function.

Drying the Refrigerant

The drying function of filter driers is facilitated by desiccant materials, such as silica gel or molecular sieves, which absorb moisture from the refrigerant. This section could explore the chemistry of these desiccants, how they interact with moisture at a molecular level, and the critical role this process plays in preventing acid formation within the system.

Installation and Maintenance

Where Are Filter Driers Installed?

Filter driers are typically installed in the liquid line of HVACR systems, strategically placed between the condenser and the expansion valve. This placement ensures that the refrigerant is filtered and dried before it enters critical components, optimizing the performance of the expansion valve and, by extension, the entire system. This section could include insights into the installation process, factors influencing the choice of location, and the impact of improper installation.

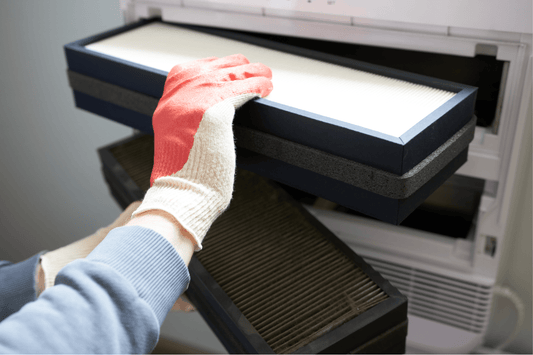

Signs It's Time to Replace Your Filter Drier

Despite their durability, filter driers do not last forever. Over time, the desiccant material becomes saturated with moisture, and the mesh may become clogged with particulates. Indicators that it's time for a replacement include a noticeable decrease in system efficiency, the presence of ice or frost on the drier itself, or a significant pressure drop across the drier. Regular system maintenance should always include an assessment of the filter drier's condition to ensure its effective operation.

Image by DC Studio on Freepik

Conclusion: Ensuring System Health with Filter Driers

As we conclude our comprehensive journey through the world of filter driers in HVACR systems, it's clear that these components are far more than just peripheral accessories. They are, in fact, vital organs of the system, crucial for maintaining the purity and efficiency of the refrigerant. By filtering out particulate matter and absorbing moisture, filter driers protect the system from the insidious threats of corrosion, blockages, and efficiency loss. Their role in safeguarding the system's components and optimizing its performance cannot be overstated.

FAQs

How often should I replace my filter drier?

The replacement frequency for a filter drier varies based on the system's operating conditions and exposure to contaminants. However, it's generally recommended to replace the filter drier every time the system is opened for maintenance or repair and at least every 2-3 years as part of routine maintenance.

Can a filter drier be cleaned and reused?

Filter driers are designed for single use. Once their desiccant material is saturated with moisture or the mesh is clogged with particulates, they must be replaced to ensure the system's efficiency and longevity.

What happens if a filter drier is not replaced?

Neglecting to replace a clogged or saturated filter drier can lead to reduced system efficiency, increased wear on components, and potentially costly breakdowns. In severe cases, it can cause compressor failure or other critical system failures.

How do I know if my filter drier is working correctly?

Signs of a functioning filter drier include the absence of moisture breakthrough (e.g., no ice or frost on the drier) and no significant pressure drops across the drier. Regular inspections and performance checks can help determine its condition.

Are there different types of filter driers for different systems?

Yes, filter driers come in various types and sizes, designed for specific applications and refrigerants. The right filter drier for a system depends on the type of refrigerant used, the system's capacity, and the operating conditions.

This guide aims to provide a comprehensive understanding of filter driers, emphasizing their critical role in HVACR system health and efficiency. By recognizing the importance of these components and adhering to best practices for maintenance and replacement, you can ensure your system operates at peak efficiency for years to come.

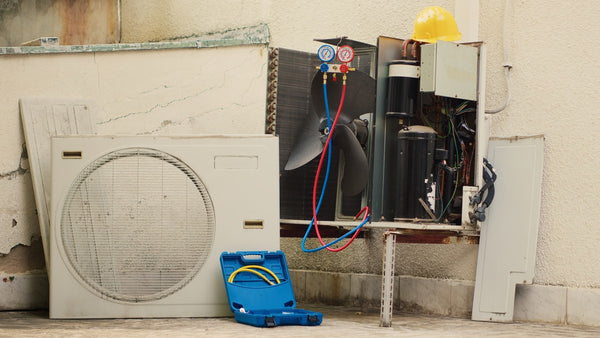

Image by DC Studio on Freepik